Discount Code: ECOPOWER at EcoFlow.com

Delta Pro Ultra

Two Inverters in One Power Station

Guest writer Mark Hicks (a.k.a. EcoPower)

The Delta Pro Ultra is a 120/240-volt split-phase power system. This is accomplished using two separate 120V 3600W inverters on opposite phases designed to work both separately and “together” to provide a variety of options for powering both 120V and 240V loads. Each inverter can handle up to 5400W of surge demand for up to 10 seconds. At 240V (using both inverters) the DPU can support up to 7200W of sustained load and up to 10,800W of surge demand.

AC Input and Output

Both inverters are bi-directional. This means they can each be used both to charge from AC (to the battery) and to provide AC output (from the battery). However, each inverter can only do one or the other (not both at the same time).

AC Bypass

Like its predecessor (Delta Pro) the Ultra has a pass-through mode. This capability has been referred to as “pass through charging” but might better be understood as “bypass mode”. Power from the wall is routed directly to loads plugged into the AC outlets on the power station and any “charging” that may take place is in excess of the load demand. For Delta Series power stations, prior to DPU, this mode was akin to having the power station and the loads plugged into a power strip on the same wall outlet and the total for loads plus charging could not exceed 15A (1800W at 120V).

Looks like this...

Functions like this...

Unlike the Delta Series models that preceded it, each DPU inverter can actually augment the AC input on its own 120V phase to provide full 3600W output per phase (7200W at 240V) when load demand exceeds input power. It should be noted that when output exceeds input there will be no “charging” happening at all. The AC input would simply reduce the amount of power needed from the battery to power the load and the inverter would be “discharging”. Only when input power exceeds load demand does the inverter charge the battery and, in that state, the bypass mode works the same as it has in prior Delta Series models with the load receiving power directly from the input source (wall outlet for example) and the inverter “charging” with whatever power is left after supplying any loads.

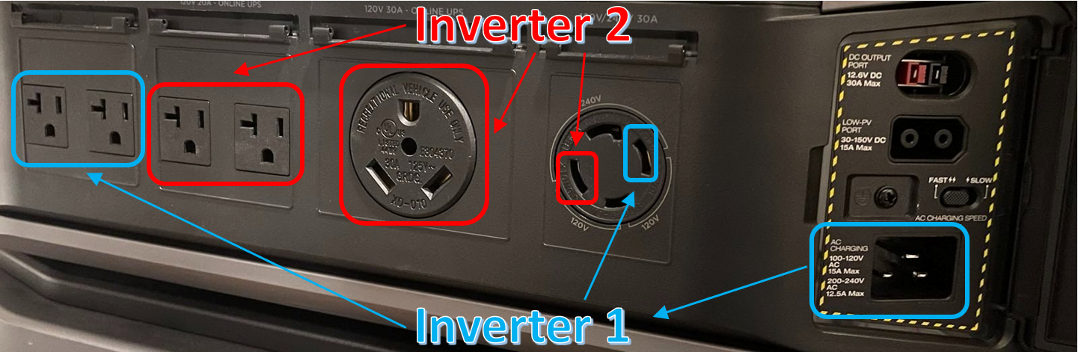

Online UPS

The “Online UPS” capability of the DPU is made possible by using one inverter to charge while the other inverter discharges. The caveats for this feature are that loads must only use the center outlets (in red above) and input must be 120V using the C20 input (on the far right, in blue, above). In this way, Inverter 1 charges the battery, as needed, and loads are powered only by the battery, using Inverter 2. This is also what allows for 0ms switch time. Since loads are always powered by the battery the removal of AC input only stops charging the battery, thus, no “switchover” time.

Backup "UPS"

If loads are plugged into the far-left outlets (in blue above) while AC input is plugged into the 120V (C20) input they will be in bypass mode. If 240V split phase input is used (via the L14-30 generator adapter for the Power I/O port, for example), all outlets will be in bypass mode. The L14-30 outlet (30A 120/240V) on the front of the DPU is always in bypass mode when any AC input is connected. In AC bypass mode, the loss of input power results in a minimum 20ms delay for one or both inverters to switch from charging mode to discharging mode. This is similar to the “EPS” (Emergency Power Supply) mode described for prior Delta Series power stations.

Fast Charge Mode (the “big caveat”)

In order to get the full 3600W per inverter (7200W at 240V) while the DPU is receiving power from an AC source the charging must be in “fast” mode. In order to use “fast” charging, and be able to get full rated output at the same time, the power source must capable of at least 1800W for 120V charging via the C20 input or at least 7200W for split phase 240V charging via the Power I/O port (using the L14-30 “generator adapter”, for example).

The reasons are technical and complex but I will attempt to simplify in order to provide some answer as to “why”. If the AC input can provide 1800W then the inverter can supply up to an additional 1800W to provide the full 3600W (per inverter). Assuming the inverter is outputting that full 1800W and there is a brief surge back to the input source when the output from the inverter ceases, the surge won’t exceed 1800W and (in fast mode) the source should be able to handle 1800W.

Now, imagine charging at 1000W in “slow” mode because your input source is a small generator that can only handle 1200W max. The inverter may have to output as much as 2600W to get to the 3600W max… if that 2600W happened to surge back, the generator might be damaged due to a surge >2X what it can handle. For this, and other more complicated reasons, the total output is limited to the charge rate when using “slow” mode (in other words 1000W “slow” charging means 1000W max output while AC is connected).

A Word About “UPS” Modes

While the ability to operate in either of the “UPS” modes has its advantages neither are optimal, in my view, in terms of long-term efficiency. Running both inverters in “Online UPS” mode causes battery depletion. Even when not charging or discharging, both inverters are ON, thus using battery power to stay on. The same is true for “Backup UPS” mode except that, in addition to that drawback, it takes at least 20ms to switch from grid to battery in an outage. This is too long for many sensitive electronics and can cause those devices to crash, reboot, or simply turn off (having to be manually restarted).

Not to discount the upside of these “UPS” features, I would suggest that some use cases still call for a purpose-built UPS unit. In many cases, the combination of a smaller dedicated UPS with a larger power station (left on standby or OFF in storage) may be more optimal. I use several small and medium size UPS units in my house to support and protect servers, computers, and other sensitive devices. Just about everything else is either fine with 20ms switch time or can restart itself without concern. I do not use EPS mode on SHP1 with Delta Pro or SHP2 with the Ultra. This keeps my standby depletion to a minimum (10-15W per DP/DPU) while still providing automatic backup to most of the circuits in my house, but keeping the inverters OFF until needed. A simpler example would be having internet, WiFi, and TV equipment on a small UPS that can support those devices for 30 minutes or so in an outage. This provides more than enough time to pull an already charged power station out of storage, turn it on, and connect the UPS to the power station. Devices powered by the UPS won’t know the difference.

A Word About Surge Demand

One aspect, often overlooked, when connecting larger power stations to home circuits (or any power station with certain loads) is the surge demand and the limitations of a power station with regard to it. Appliances such as fridges, freezers, A/C units, water pumps, etc. are examples of loads that require much more current to start up than they do to operate (once fully running). In most cases the surge demand is momentary (a split second) but the power has to come from somewhere and in the case of battery powered AC inverters, this can be a challenge.

A typical fridge, for example, might require 1000W to start up but only use 100-150W when running (and may only run an average of 15 minutes per hour). A larger 4-ton heat pump or A/C unit may require 6000-12000W to start but only 1500-2500W once running (and, again, may only run part of the time as heating/cooling are required). The DPU can support up to 5400W of surge, per inverter, for up to 10 seconds. Most surge demands will not last even a full second. However, as existing load increases, this “surge headroom” decreases. That means, for example, if you’re already running 2000W of established load on an inverter with 5400W maximum surge capacity the “headroom” is only 3600W at that point. For a 120V fridge that demand will impact only one of the two DPU inverters while a 240V A/C unit will put surge demand on both inverters.

This is not a problem if the load you want to run is within the surge rating of the power station. However, if your load is anywhere close to the max rating and you have other loads already running this can cause overload. This is a particular concern for those contemplating a “whole home backup” solution or even “partial home backup” that includes high surge loads like A/C or well pump. I can start my 4-ton heat pump using only a single DPU even if I force it into stage 2 test mode (which has the highest surge demand). That is because my heat pump is 107LRA and the DPU can support up to 120LRA. Still, my heat pump can use most of the surge headroom all by itself. If I have a few basic loads running (say 1000W or so) starting my heat pump is still not a problem and, once running, it often settles at ~1600W. But if I have several other things running, or even just the dryer (~5000W+ all by itself), then I no longer have enough surge headroom and if the heat pump tries to start at that point the DPU will trigger overload protection.

It should also be noted that phase balance has an impact here. While pure 240V loads will typically put equal load on each of the two 120V inverters any 120V loads put load on only one inverter. Therefore, whichever phase is more heavily loaded determines the maximum surge headroom available. If, for example, you have 1000W of load running that is divided equally (500W from each inverter) and then start a load of dishes, putting an additional 1000W load on only one inverter, that one inverter is now at 1500W and has only 3900W of headroom left for surge demand which means that a 240V A/C unit that requires 8000W to start (4000W from each inverter) may overload the DPU. This is where using multiple DPUs (such at 2 with the 50A Hub or 2-3 with SHP2) comes into play and where balancing battery capacity across the system is a consideration, but that is a whole other article…